How are control engineers improving the sustainability of irrigated agriculture?

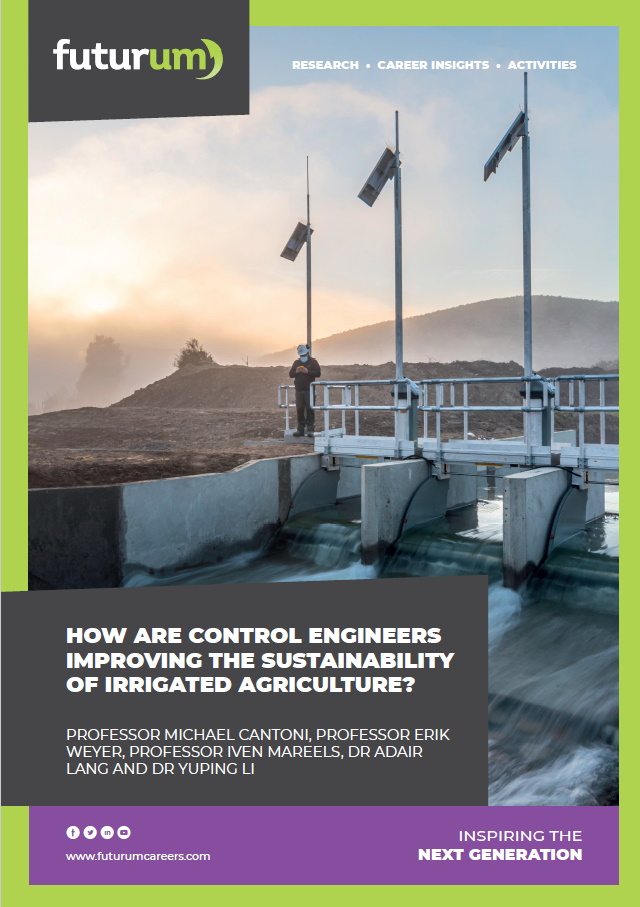

Globally, less than 60% of the water diverted into irrigation networks is used productively. This inefficiency is partly due to outdated infrastructure and manual operating practices that can result in wasteful spillage at the end of the open-water distribution channels and poor service to farmers. In Australia, control engineers from the University of Melbourne and Rubicon Water have developed a system that automatically adjusts water supply to more efficiently meet demand.

TALK LIKE A CONTROL ENGINEER

Actuator — a device for imposing the value of a variable as a control input. For example, an adjustable gate for setting the flow between sections of an irrigation channel

Compensator — the part of a feedback control system that determines the actuator settings across time in response to sensor measurements. It is often implemented in software on a computer

Feedback control — achieving desired behaviour by measuring what is happening and using this information to adjust the control inputs

Off-take — extraction of water from an irrigation channel

Pool — in an irrigation network, a stretch of open channel with gates at each end. Pools can range from hundreds to thousands of metres in length

Sensor — a device that produces measurements of a variable

Setpoint — the desired value of a controlled variable. For example, in irrigation networks, there are setpoints for the water levels at the supply points to irrigators

Signal — the values of a variable across time. For example, the varying water levels and gate flows in an automated irrigation channel

Supply point — in an irrigation network, where off-takes occur

Humans have been finding innovative ways to divert water for thousands of years. In Ancient Egypt, canals were used to distribute water from the Nile across large plains to grow crops such as wheat and barley, while in Southeast Asia, people learnt how to partially flood fields to increase yields of rice. As irrigation can double or even triple crop yields, technologies such as these laid the foundations for much of modern agriculture.

At the University of Melbourne, Professor Michael Cantoni and Professor Erik Weyer are collaborating with engineers at Rubicon Water, including Professor Iven Mareels, Dr Adair Lang and Dr Yuping Li, to improve the efficiency of gravity-fed irrigation networks. They are applying techniques from control engineering to automate the networks of open channels used to distribute water to farms. Their work is reducing water losses from irrigation networks and improving the quality of water distribution services for farmers.

What challenges do irrigation networks face?

“Half of the world’s accessible fresh water is used in large-scale irrigation for our food and natural fibre production,” explains Iven. Population growth, food security and rising living standards are driving increased demand for irrigation water. On the other hand, climate change and competing uses for water outside agriculture impact the supply side. “Without large gains in water productivity, the world could run out of economically available water,” Iven warns.

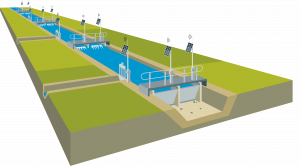

Most agricultural water distribution systems consist of a network of open channels and the flow of water through the system is powered by gravity. Channels are partitioned by gates into stretches of stored water, called pools. The gates are used to set the flow of water between these pools. To irrigate their fields, farmers extract water at supply points.

It is important that the supply of water through the network is set to meet the demands of farmers extracting water. In networks with limited opportunities to adjust gate settings, unpredicted changes in demand can result in wasteful spillage of water out of the network and poor service to irrigators, which can limit efforts to improve on-farm efficiency.

Total Channel ControlTM

These challenges motivated the team to enhance the capabilities of irrigation networks by developing ‘Total Channel ControlTM’ (TCC). TCC is an automatic control system for maintaining desired water levels at the supply points in an irrigation network, so that the water demands of farmers can be reliably supplied under the power of gravity.

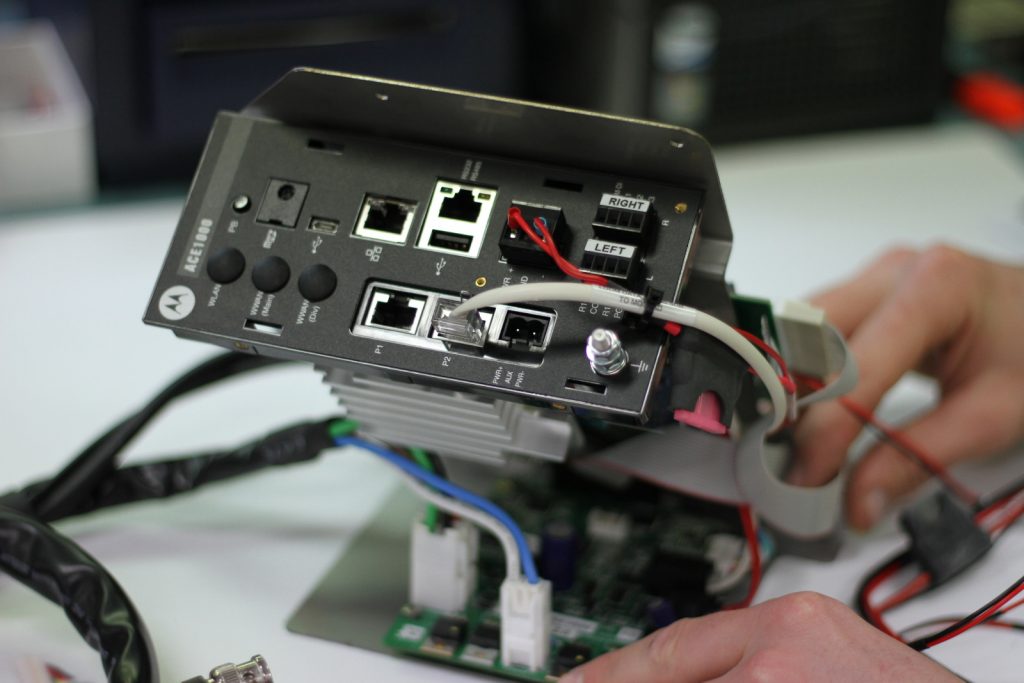

With TCC, the gates between pools are equipped with sensors to monitor the local upstream water level, actuators to adjust the gate positions to set the downstream flow, and radio communications for the exchange of information between the gates. “The goal is to coordinate the gate flows along the channels to keep water levels at supply points close to target values as demand varies across the network,” explains Michael.

Providing a high-quality service to irrigators requires steady water levels at supply points. “However, the scale of the system and uncertainty in future demand for flow make the problem of coordinating the gates non-trivial,” says Michael. To address the challenge of supplying water to match unpredictable demand, the TCC system relies on feedback control.

The importance of feedback control

“Feedback control is one of the essential elements of life as we know it,” Iven says. For example, it keeps warm-blooded animals at a constant internal body temperature. If our body becomes too warm, we sweat to reduce our temperature, while if we get too cold, we shiver to warm up. In this way, our core body temperature is maintained close to 37 °C.

In feedback control, adjustments are made to the system when the measured value of a quantity does not match its target value. It involves observed signals, produced by sensors, and signals imposed on the system by a compensator via actuators in response to the observed signals across time. “Together, the interconnection of the system and compensator is a feedback loop,” says Michael.

Feedback in TCC causes the gates to respond to measured water level errors by adjusting the gate flows along the channel. Under steady operating conditions, the upstream inflow to each pool will match the off-take and downstream outflow, and the water level at supply points will remain constant. Any changes to the off-take or downstream demand will perturb the net flow of water and cause a change in local water level.

With TCC, the outflow gate at the downstream end of each pool measures the difference between the observed water level and the desired water level. This information is communicated to the inflow gate, which determines how the upstream inflow to the pool should be adjusted in order to return the downstream water level to the desired setpoint. “This feedback control action at the upstream gate also changes the net flow of the upstream pool, resulting in water level error there and adjustment of its upstream gate by feedback compensation,” explains Erik. “This continues automatically, until the inflow at the top of the channel has been adjusted to match the change in demand.”

How do models inform the design of feedback loops?

The data furnished by the water level sensors and the actions taken by the gates’ automatic adjustment mechanisms form a feedback loop that keeps water levels at the desired setpoint, regardless of changing demand.

The design of feedback loops can be complicated. “It is well known that poorly designed feedback loops can lead to very undesirable outcomes, such as the excitation of waves that can lead to channel damage and flooding,” says Yuping.

The team avoids the possible pitfalls of feedback by using mathematical models to inform the design of the compensators for each pool. For example, these models are used to guide the selection of compensator parameters and used in simulations to validate performance ahead of operational deployment. The models are informed by the physics of channel flow and encode the dynamic relationships between upstream inflow, downstream outflows, supply point off-takes and downstream water levels. The models are calibrated against experimental, historical and synthetic data.

Successes of TCC

A key advantage of TCC is that the supply of water from the environment is adjusted to match the varying demand, which avoids spillage and wastage of unused water at the end of distribution channels. Automation means the system does not require human input to adjust water flow when demand changes. Also, the system does not need predictions of future demand as the feedback control system autonomously reacts to real-time changes in demand, although when available, such information can be incorporated to enhance performance.

To date, Rubicon Water has installed over 35,000 control gates in irrigation networks around the world. The Goulburn-Murray Irrigation District in northern Victoria, Australia, has been operating under TCC for more than a decade, resulting in water losses being reduced by 50% compared to pre-automation operations. Development of the TCC technology continues as Rubicon Water expands into new markets.

As our global demand for water increases, control engineers will play a key role in helping to ensure our world has water security.

Reference

https://doi.org/10.33424/FUTURUM320

TOTAL CHANNEL CONTROLTM

TOTAL CHANNEL CONTROLTM

University of Melbourne and Rubicon Water, Australia

Field of research: Control Engineering

Research project: Automation of open channels for gravity-powered water distribution

Funders: Australian Research Council, Rubicon Water, University of Melbourne

ABOUT CONTROL ENGINEERING

Control engineers are often responsible for the design and implementation of crucial components in larger engineering systems. “Feedback control systems enable intended behaviour to be achieved in unpredictable operating environments,” explains Michael. For example, in power and water distribution networks, control systems allow the supply of electricity and water to be automatically adjusted to meet unpredictable changes in demand.

“Control engineering is everywhere around us,” says Iven. “For example, our mobile phones use just enough power to make a call, but as little as possible to avoid draining the battery.” Cruise control on a car maintains the car’s speed and the autopilot in aircraft maintains specified altitude and direction. Thermostats use simple controls to keep your home at a constant temperature, regardless of the weather outside.

Bridging the gap between academia and industry

The partnership between the University of Melbourne and Rubicon Water underlies the initial success and continued development of TCC. “As the industry partner, Rubicon Water is the source of real-world problems that need solutions,” Erik says. “The university team of academics contributes expertise in modelling and control of dynamic systems.” In all fields of engineering, it is important to work with stakeholders to ensure the needs of end users are met. To improve irrigation network efficiency, for example, the team works with water authorities and farmers to learn what each requires from an automated irrigation network. “As well as having strong technical skills, control engineers must also have the interpersonal skills necessary to interact with different stakeholders,” says Yuping.

The future of control engineering

“Control engineering is a discipline that has very wide applicability,” says Iven. It is essential in all modern industrial settings, playing a critical role in improving the energy and resource efficiency of processes. While this project is reducing water waste, control engineering can also increase sustainability in other contexts. “Control engineering has a significant role to play in making our industrial society more sustainable,” says Erik.

Pathway from school to control engineering

• “To become an engineer, maths and physics are fundamentally important at both school and university level,” says Michael. “Computer science is also important.”

• Computer programming skills are essential in most engineering jobs, so learn coding languages as soon as you can. “Working on hobby projects that involve coding is a great way to practice and develop these skills,” suggests Adair.

• “Keep studying maths, as it is the foundation of engineering,” advises Adair. “Don’t just learn the formulas, try to understand the theory and how to use maths to solve problems. This is what makes an engineer.”

• If you are interested in the biomedical applications of control engineering, it will be useful to study chemistry and biology.

• At university, control engineering is taught within general undergraduate engineering degrees, such as electrical, mechanical, aerospace and chemical engineering. Some universities will then offer postgraduate degrees specifically in control engineering.

Explore careers in control engineering

• Control engineers can find themselves working in a wide range of industries. From contributing to the green energy revolution in electric power grids, to enhancing the sustainability of water and transportation networks, control engineers are always in demand. You could also find yourself developing artificial intelligence for surgical robotics or designing autopilots in the aerospace industry.

• Prospects provides information about careers in control engineering, including the work you are likely to do, the skills you will need and the salary you can expect: www.prospects.ac.uk/job-profiles/control-and-instrumentation-engineer

• The Control Systems Society of the Institute of Electrical and Electronics Engineers has published a report on the impact of control technology with examples of how control is used in a huge range of applications, from drones to medical rehabilitation to Formula One racing: www.ieeecss.org/impact-control-technology-2nd-edition

Meet the team

Professor Michael Cantoni

Professor of Electrical and Electronic Engineering, University of Melbourne, Australia

What were your interests when you were younger?

My main interest was in spending time outside with my brother and neighbours – riding our bikes, kicking about in nature reserves, swimming in the ocean. When stuck inside, I spent hours playing with LEGO and with an early personal computer. After my family relocated from one side of Australia to the other, I became more interested in school and playing music.

Who inspired you to become an engineer?

My father is an electrical engineer, my mother trained as a civil engineering draftsperson and I have grandparents who were technicians – so perhaps it is in my genes! At the end of high school, it was maths and physics that I enjoyed the most, so engineering seemed like a natural path to follow at university.

What do you most enjoy about your job?

I enjoy the process of applying mathematical thinking to achieve desired outcomes and to balance competing objectives. There is such a wide range of practical contexts in which control engineering is relevant – water and power distribution networks, heating and ventilation systems, telecommunications, manufacturing and aerospace.

What has been the highlight of your career?

I am proud to have contributed to the success of Rubicon Water, both through my own research and by training engineers who played a key role in translating innovations from research into real-world outcomes. Iven, Erik and I jointly received an award for this work from the Control Systems Society of the Institute of Electrical and Electronics Engineers.

Professor Iven Mareels

Non-executive Director, Rubicon Water, Australia

What were your interests when you were younger?

At school, I liked studying, reading and sports (especially handball and table tennis). At home, my dad was handy around the house so we did a lot of home projects together. I enjoyed working with my grandad in his timber workshop, where I became interested in creating and building things.

Who inspired you to become an engineer?

My dad was an electrical engineer, as were two of my uncles, so engineering was always in the family. I was encouraged to take things apart and put them together again, and my dad would explain technical ideas to me. At school, I was advised to study classics at university, but my interest in science and maths always seemed to point me towards engineering. In the end, I got sufficient marks to go to Gent University in Belgium, where I studied electromechanical engineering.

What have been the highlights of your career?

The collaboration with Rubicon Water is certainly one of the highlights of my career. In 1998, when I worked at the University of Melbourne, I was approached by someone at Rubicon Water who was a former engineering student of mine. Rubicon Water was having control problems with an irrigation channel system they were managing, and my former student wondered if I could help. The University of Melbourne has worked with Rubicon Water ever since.

I am also proud to have trained over 50 PhD students. I know that these new generations of engineers will change the world, which is greatly rewarding. I have an ongoing interest thinking about how best to educate young engineers, in the context of new tools, such as artificial intelligence, which affect how we perceive and use knowledge. I want to see science and engineering make a positive difference for people and for society.

Professor Erik Weyer

Professor of Electrical and Electronic Engineering, University of Melbourne, Australia

What inspired you to become an engineer?

At school, I always liked maths, and then later, physics. At university, it was natural for me to study something where mathematics played a big role.

What qualities have made you successful as an engineer?

I have always paid attention to details. The overall design and concept of a project are, of course, very important. But, for a project to work, all the details also need to be right. At the same time, I like to do things my own way, which sometimes has led me to new ideas and improved methods for problem solving. Even if I discover that the standard approach works better than my new suggestion, I know I have learnt something new from trying it my own way.

What do you most enjoy about your job?

I enjoy working on interesting and challenging problems. The first time we tested a control system on an irrigation channel was a memorable moment. Although everything worked well in simulation on a computer, I still had worries that we may have overlooked something and that it wouldn’t function when tested on the real channel. It was very rewarding to see that it worked. There is a satisfaction in seeing that a system works after you have designed, implemented and tested it.

Dr Adair Lang

Innovation Manager, Rubicon Water, Australia

What inspired you to become an engineer?

During high school, I didn’t really know what an engineer was. I pursued my interests in physical sciences and maths and, while still in school, I was fortunate enough to undertake work experience at the National Measurement Institute in the Australian Government’s Department of Industry, Science and Resources. This experience led me to enrol in physics, maths and introductory engineering courses at university. After learning more about engineering, how it sits at the interface between scientific study and practical application, I chose to major in electrical systems.

What motivated you to do a PhD in engineering?

After completing a master’s degree in engineering, I spent three years working as a control engineer at Rubicon Water. However, I had a desire to gain more knowledge and to develop new research skills, so I returned to university to do a PhD. In my research, I used mathematical analysis to find solutions to problems that arise in irrigation networks. This involved developing computer models and methods to solve complex maths problems. Fortunately, I was able to continue working part-time at Rubicon Water during my PhD, keeping me close to the practical applications of engineering while conducting theoretical research.

What does your current role at Rubicon Water involve?

I contribute to the roadmap for the technology being produced by the company. This involves meeting with managers and the CEO and discussing ideas with clients and sales staff. Part of my work is prioritising the large number of potential products to ensure that the company focuses on the highest value ideas first. I also lead the research and development of the control engineering side of the company. This involves computer coding, mathematical analysis, writing specifications for products and working with other teams to implement solutions.

What do you most enjoy about your job?

I enjoy designing and implementing novel solutions to real-world problems that have a large impact on saving water and increasing farm productivity. I like getting involved with multiple projects, both at a technical level and in a coordination role. A real highlight is when a solution is deployed and the client is able to witness the benefits of automation in their water distribution network.

Dr Yuping Li

Senior Control Engineer, Rubicon Water, Australia

Who inspired you to become an engineer?

My mum is an electronics engineer and she inspired me to follow this career. As a child, I liked playing with a Rubik’s Cube and I also enjoyed painting, and still do today.

What does your job as a control engineer involve?

My research interests are in the distributed control of large-scale water distribution networks, model approximation and validation. At Rubicon Water, I do research and development work on irrigation networks and provide technical training on our systems, both internally and to customers. Part of my operational work is to identify control issues within existing irrigation networks and organise ways to rectify them.

What do you most enjoy about your job?

I enjoy seeing a design implemented in a real system and achieving the performance aims that we were targeting. Working on irrigation networks, I get the opportunity to see control engineering problems in practice, which motivates me to learn new techniques and use the knowledge that I have to help solve them. I am proud of the fact that the CEO of Rubicon Water recently gave a presentation to the board of the company which heavily featured work that I have contributed to over the past four years.

The team’s top tips

1. Engineering is about creating the world around us, which begins with a problem to solve. Know that there will be an engineering pathway to a solution (within the limits of feasibility – not everything we dream of is feasible!).

2. Creativity is given to all of us – it is part of being human. Use your creativity to help others and don’t lose the joy of it.

3. Don’t be satisfied with a superficial understanding of something, or the first solution you find to a problem. Instead, be a lifelong learner and constantly seek out new challenges

4. Respect what you do not know. Always ask questions to learn more.

Do you have a question for the team?

Write it in the comments box below and the team will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)