Prostheses for people: matching the person and their new limb

Worldwide, the majority of amputees do not have access to a useful prosthesis. This is especially true in lower and middle income countries (LMICs) where limb loss may be more common and services less accessible. Mechanical engineers Professor Laurence Kenney and Dr Alex Dickinson are working with people in different parts of the world to make prostheses as accessible and useful as possible

TALK LIKE A MECHANICAL ENGINEER

MECHANICAL ENGINEERING – the branch of engineering that focuses on the design, construction and use of machines

ORTHOPAEDIC – the branch of medicine that addresses deformities or losses of bones and muscles

PROSTHETICS – the branch of science/ medicine involving the design, construction and fitting of artificial body parts

PROSTHESIS – an artificial body part

UPPER LIMB – includes the shoulder, arm (the upper arm), elbow, forearm (the lower arm) and the hand

PROSTHETIST-ORTHOTISTS – a medical practitioner specialising in prosthetics and orthopaedics

NEWTON (N) – the unit of force

Human limbs are complex, so building mechanical replacements is no easy task. Despite major steps forwards in the science of prosthetics, there are still barriers to overcome in terms of making prostheses accessible, useful and specific to their user.

When Professor Laurence Kenney and Dr Alex Dickinson began their projects, they recognised that engineering alone cannot provide all the answers and that interdisciplinary collaboration would be essential to build devices that work for real people in the real world.

PROSTHETICS: FROM SCIENCE TO APPLICATION

Limb losses can occur from a multitude of injuries, diseases or genetic abnormalities. The science behind prosthetics is always becoming more sophisticated, with the most advanced prostheses having almost the same range of movements and functions as the limb they replace. However, such sophisticated models are staggeringly expensive and, for most prosthesis wearers and the healthcare systems that support them, more affordable solutions are needed. Alex explains, “Another issue is that the more precisely a prosthesis matches the function of the real limb, the less durable it is likely to be.”

Every person in need of a prosthesis will have a different set of circumstances, a different body on which the prosthesis needs to fit and differing requirements for what they need the prosthesis to fulfil. For instance, while some people may want a prosthesis purely for aesthetic purposes, others may need a functional prosthesis to sustain their livelihood. Overall, this means that it is impossible to mass-produce prostheses if they are to be effective; a bespoke approach is needed to tailor each prosthesis to the person it will fit.

A FOCUS ON LOWER MIDDLE INCOME COUNTRIES

Although the precise figure is not known, it is estimated that around 57.7 million people globally have suffered from a limb amputation stemming from a traumatic incident. Around 38% of these suffer from upper limb loss. “It’s also estimated that 64% of amputees live in LMICs, and their average age tends to be younger than in higher income countries,” explains Laurence.

There are several reasons why the majority of amputees may be concentrated in LMICs. Many of these nations have experienced conflict in recent decades, and even if the war may have ended, its legacy can live on in the form of unexploded landmines. When a landmine is stepped on, the ensuing explosion can easily lead to the victim losing a limb. “Other common causes of upper limb loss in LMICs include road traffic accidents and poor access to medical services, which could prevent a relatively minor affliction from progressing to a stage where amputation is needed,” says Laurence.

THE CASE OF CAMBODIA

Cambodia, where Alex’s project is focused, is a prime example of a nation with a higher-than-average need for prostheses. Brutal conflicts in the 1970s and 1980s, such as during the Khmer Rouge regime, included the placing of as many as ten million landmines. This has led to the nation having one of the highest amputation rates in the world. “Cambodian authorities and charities that work in the country have a lot to be proud of in terms of clearing landmines, providing prosthetic limbs and supporting prosthetic limb users with other services,” says Alex.

Despite these successes, a lot of work remains. “You may think that the barrier to helping these people is the cost of prosthetic limbs, but we already have some very robust, long-lasting and relatively inexpensive prostheses,” says Alex. “Bigger barriers to providing prosthetic limbs to people in LMICs are the lack of trained professionals and access issues, as many people live far away from clinics and are unable to travel or take time away from work.”

UGANDA AND JORDAN

“Globally, the World Health Organization estimates that only between 5 and 15% of people who need a prosthesis have access to one,” says Laurence. In Uganda, one of the least developed countries in the world, his team found that the absence of government support meant that the orthopaedic workshops in government-run hospitals were typically under-supplied with the equipment and materials they needed. “The lack of a coordinated purchasing system means that prices are high and patients often have to buy the materials they need themselves,” says Laurence. “For instance, we found that the cost of polypropylene, a plastic commonly used in prosthetics and many other applications, was about five times higher in Uganda compared to the UK.”

Jordan suffers less from poverty than Uganda and has a developed clinical infrastructure with well-trained staff. However, regional conflicts are catalysing the loss of limbs and destabilising the economy. “While service provision in Jordan is better than in Uganda, cost remains a barrier to many,” says Laurence. The different needs of people within these two countries are supplying useful lessons for the team, making it clear that there is no ‘one size fits all’ solution to making prostheses accessible to those who need them.

EXPLORE A CAREER IN MECHANICAL ENGINEERING

• Alex recommends getting as much experience as possible, such as through work experience or volunteering. Contacting a range of relevant organisations close to you can open doors – Alex recalls spending his school and university holidays working in a Formula 3 team, helping a team restore a crashed Hurricane WW2 fighter, and investigating failed helicopter parts.

• The Institute of Mechanical Engineers runs activities for schools, supports teachers, and provides useful careers advice.

• The Royal Academy of Engineers has a comparable range of resources with a broader engineering focus.

• Talking to your school about bringing engineering into the classroom can provide inspiring experiences and potentially useful contacts or entry points into the field. The Primary Engineer Programme and Stem Ambassador Programme both provide courses for students of all ages.

• According to Prospects UK, starting salaries for mechanical engineers on graduate training programmes range from £20,000 to £28,000.

PATHWAY FROM SCHOOL TO MECHANICAL ENGINEERING

Both Alex and Laurence say that A-levels (or equivalents) in maths and physics are typically required for undergraduate degrees in mechanical engineering. Alex recommends thinking outside the box for different additional subjects, citing the importance of a broad skillset. Options include chemistry, languages, electronics, computing, design, music and art.

PROFESSOR LAURENCE KENNEY: FIT-FOR-PURPOSE-AFFORDABLE BODY-POWERED PROSTHESES

Laurence’s project involves teams working in Uganda and Jordan to understand the differing regional and individual challenges facing effective use of prostheses in those nations. With this information, they are improving body-powered prostheses.

Reference

https://doi.org/10.33424/FUTURUM313

© Laurence Kenney

© Alex Dickinson

© Alex Dickinson

© Alex Dickinson

© Alex Dickinson

Body-powered prostheses are upper limb replacements that incorporate mechanical components that can be moved by the wearer, allowing them to grasp objects. “Traditional body-powered prostheses consist of a mechanically operated ‘hand’, often a ‘split hook’, attached via a cable to a shoulder harness,” explains Laurence. “Movement of the shoulder pulls on the cable which in turn either pulls the ‘hand’ open or closed, depending on the configuration.” Designs are relatively low-cost and typically cope well with wear and tear.

However, body-powered prostheses also tend to be unpopular. Designs have changed little over the last 100-odd years and users report limited functionality and some discomfort, leading to high rates of rejection. One fundamental issue lies in the inefficiencies of the underlying mechanics, which is where Laurence’s expertise can help. “In a worst-case scenario, a force of over 130 N was needed to get the prosthesis to grip an object with a force of 15 N!” says Laurence. “This means that operating the prosthesis can quickly become tiring.” The team also found that the range of movement when using such body-powered prostheses was limited, including both where the ‘hand’ could be positioned relative to the rest of the body, as well as the ability to fully open or close the ‘hand’.

LIVED EXPERIENCES

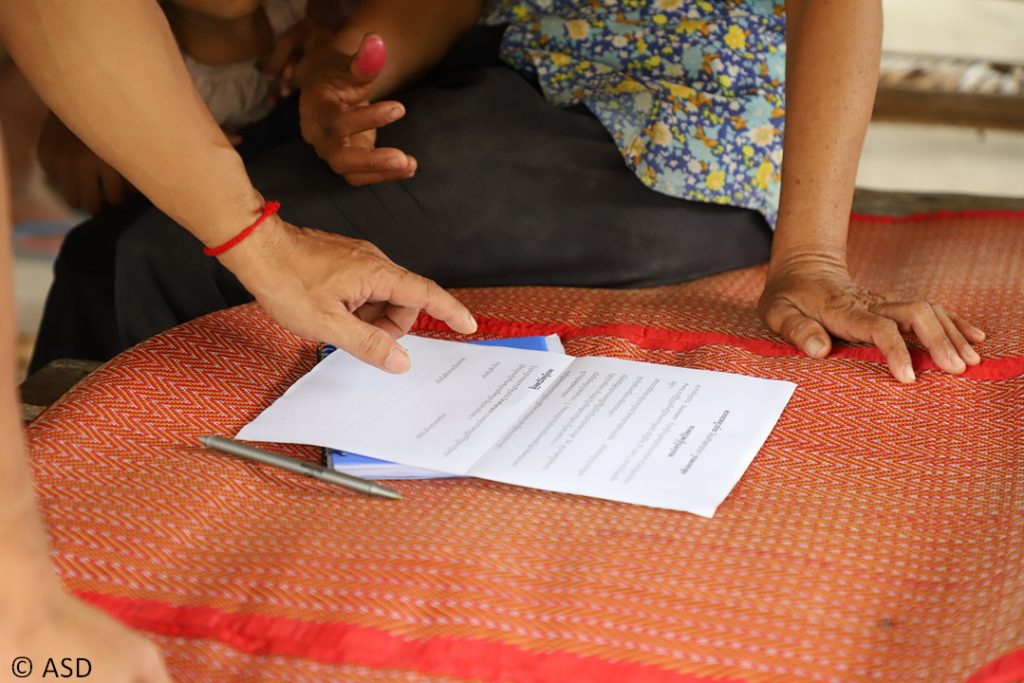

Though these functional benefits and limitations can be explored in a workshop, understanding how they are used in the real world involves interacting with prosthesis users. Laurence’s team includes a social scientist and a health psychologist, who specialise in collecting such information. These two individuals trained teams of interviewers within Jordan and Uganda. “Once trained, the interviewers invited people with upper limb absence to talk about their experiences and expectations of prostheses,” says Laurence. “The researchers then used a technique called ‘thematic analysis’ to pull out the key features and themes from the recordings.”

Their findings were fed back to the mechanical engineers. Though they originally planned to concentrate on increasing the efficiency of prostheses, the findings from the interviews suggested that development of a simpler overall design may be of more benefit to prosthesis users. “We have decided to design a hand which doesn’t rely on shoulder harness-control for its operation,” explains Laurence. “The hand design problem is a compromise between the appearance of the hand and its function. We learnt that the ability to perform tasks such as farming and household chores are important to the population we were designing for.” Comfort was also highlighted, so the team has expanded its work to include designing a socket that can be made easily, fitted comfortably and potentially repaired locally.

PARTNERS

As well as working across different scientific disciplines, there is a lot of value in working with partners from outside academia. In Jordan, the team has been advised by the International Committee of the Red Cross (ICRC) and Médecins Sans Frontières (MSF), two well-known and respected international charities that have plenty of experience working with LMICs, both understanding limitations and opportunities, as well as having useful networks with which the team can connect. “These organisations have been very helpful in keeping our team grounded in the reality of delivering prosthetics services in LMICs,” says Laurence.

The Uganda team has also recognised this value. “One of our team, Professor Louise Ackers, also heads up the Knowledge4Change charity, and its involvement in supporting placements in Uganda has been very helpful,” says Laurence. “For instance, early in the project, a number of Salford University students and a couple of NHS trainee clinical scientists carried out small projects in Uganda, which greatly helped us to focus our design efforts.”

IMPACTS AND HIGHLIGHTS

“I think our impact to date has been in somewhat unexpected areas for an engineering project,” says Laurence. “For example, identifying and highlighting the specific issues with the Ugandan prosthetics services has framed the problem, possibly for the first time, and we are trying out ways to address these issues.” By expanding its focus to look at the issue from the perspective of individuals’ lived experiences, the team has uncovered wider challenges beyond the mechanical design issues that they initially identified.

Laurence believes this engagement with real society has brought its personal rewards too. “The project has, without doubt, been a career highlight for me,” says Laurence. “I have thoroughly enjoyed working with enthusiastic and brilliant engineers, social scientists, clinicians and psychologists, as well as learning an enormous amount about the challenges of designing fit-for-purpose prostheses.” The project is not finished yet and the teams remain enthusiastic to find ways to further their work beyond the scope of the project.

PROFESSOR LAURENCE KENNEY

PROFESSOR LAURENCE KENNEY

School of Health and Society, University of Salford, Manchester, UK

FIELD OF RESEARCH: Rehabilitation Technologies (Mechanical Engineering)

RESEARCH PROJECT: Assessing the body-powered prosthesis requirements of amputees in Uganda and Jordan to develop optimised prostheses and support improved provision and uptake

FUNDERS: Engineering and Physical Sciences Research Council (EPSRC) and National Institute for Health Research (NIHR)

Global Challenges Research Fund

HOW DID LAURENCE BECOME A MECHANICAL ENGINEER?

WHO OR WHAT INSPIRED YOU TO BECOME AN ENGINEER?

My dad was a chemical engineer, and I can remember taking down his master’s thesis from the shelf in the front room and being intrigued by the maths, which at that age seemed like a really exciting puzzle to decode. I also very much enjoyed maths at school.

WHAT LED YOU TO SPECIALISE IN REHABILITATIVE TECHNOLOGIES?

As a child, I had Perthes Disease, which is a softening of the top of the thigh bone due to a restricted blood supply. For periods, I was in hospital and, later, underwent a quite complex operation. For some of the time during these periods, I was a wheelchair user. The operation and rehabilitation were both very successful and I went on to take up rock climbing and hill walking as an adult. The potential positive impacts of rehabilitation engineering were, therefore, very clear to me!

WHAT ARE YOUR PROUDEST CAREER ACHIEVEMENTS, SO FAR?

For a couple of years in the late 1990s, I worked in the Netherlands as part of a team developing an implantable electrical stimulator which could be used by people with impaired walking. We worked with a UK-based company, Finetech Medical, who later made the device available for regular clinical use. I think my proudest moment was witnessing the first operation to implant the system.

WHAT CHALLENGES WILL BE ADDRESSED BY MECHANICAL ENGINEERS OF THE FUTURE?

The two obvious challenges are green technologies to address the climate emergency, and the delivery of more efficient and better healthcare. Personally, it is pleasing to see many more engineers now choosing to focus on these areas rather than, for example, developing ‘better’ weapons.

LAURENCE’S TOP TIP

If it interests you, choose mechanical engineering! It opens up enormous possibilities for a varied and rewarding

DR ALEX DICKINSON: A STEP CHANGE IN LMIC PROSTHETICS PROVISION THROUGH COMPUTER AIDED DESIGN, ACTIMETRY AND DATABASE TECHNOLOGIES?

Alex’s project involves working in Cambodia to find data-technology solutions to help people access prostheses that work for them. Developing these solutions also involves developing a deep understanding of the context of the issue.

TECHNOLOGY TO TAILOR PROSTHESES

Alex’s team identified that, in Cambodia, it was not the functionality of prostheses but rather access to surrounding services that was limiting uptake and use of prostheses. “Instead of developing new prosthetic limbs, we wanted to see whether we could support improving access to prosthetics services by developing and introducing digital tools,” he explains.

For instance, given that every person who needs a prosthesis will have different body characteristics and residual limb (sometimes called ‘stump’), there is a need to account for these individual differences to ensure their prosthesis is comfortable and useful. “What makes matters worse, over time the residual limb changes shape considerably! 3D scanning can measure the shape of a residual limb, and we wanted to enable this procedure to be performed by a travelling prosthetist to assess when a new prosthesis is needed, so that people don’t need to make long journeys or take time off work,” says Alex.

The team is also investigating fitting digital sensors on prostheses, which record how patients use the limbs in their daily lives, helping prostheses be better tailored to their needs. “By bringing together the data from these different digital tools, we can understand more about the value offered by prosthetic limbs and services, which will help charities and the government to justify why they need ongoing funding, and to make best use of it,” says Alex. Given that prostheses need to be replaced every few years, this recorded data will also help the creation of a person’s next prosthesis more closely fit their needs.

BUILDING ROBUSTNESS

Because Alex’s team needs its sensors and scanners to be used by researchers and prosthesis users in the wider world, rather than solely by clinicians in hospitals or labs, there are a number of other factors to bear in mind. “It is important that our sensors and scanners are durable so that they work well in hot temperatures and dusty, humid environments, so part of our work is testing and selecting from the best sensors and scanners already available,” explains Alex.

The team also wants to ensure its devices are reliable, giving accurate and meaningful measurements. “For instance, it’s important that 3D scans give the same information if the same leg is scanned several times, or by different people,” says Alex. “On top of that, we need to collect, store and synchronise a person’s clinical data records safely, and ensure we have their informed consent, so a big part of our project was creating a system which would manage their data in a secure and ethical way.”

PARTNERING UP

“It is essential for our research to include a team with a wide range of experiences, because it is impossible for any one specialism to have all the skills needed to do this kind of work,” says Alex. While biomechanical engineers understand how the body works and how it can be measured, computer scientists and software engineers can ensure that data is managed effectively and kept secure.

In addition, it is important to ensure that these measurements and recordings actually have useful applications for their end users. “Our approach involves working carefully with a healthcare psychologist, clinicians, a business modeller and prosthetic limb users themselves to understand what we actually need to measure – measuring something that matters to the person and their community,” explains Alex.

Outside of science, Alex’s team partnered up with the charity Exceed Worldwide, which helped their work reach the people that needed it most. “Exceed Worldwide provides prostheses and runs a school which trains people to become certified prosthetist-orthotists who design and fit people with prosthetic limbs, and technicians who make and repair them,” he says. Being able to access this network ensured that the team’s creations would have practical value.

SUCCESSES AND NEXT STEPS

The team has made a lot of progress in developing and deploying digital tools and has confidence that its tools work in the real world. This will help inform the further development of similar tools, acting as a ‘benchmark’ to compare future efforts to. “Another big success in my opinion is that we did this work with four Cambodian student prosthetist-orthotists, as part of their final-year projects,” says Alex. “They are now more confident to do research and were able to present their work at an international prosthetics and orthotics conference.”

Next, the team hopes to expand its work further afield. “By analysing similar data in many more places, we can help clinics and other service providers to make more confident decisions about which are the most effective prosthetic limbs for their patients and let them build the evidence to ensure they can keep getting funding to do their highly important work of providing people with prosthetic limbs,” says Alex.

DR ALEX DICKINSON

DR ALEX DICKINSON

Associate Professor in Mechanical Engineering, University of Southampton, UK

FIELD OF RESEARCH: Mechanical Engineering

RESEARCH PROJECT: Developing digital measurement tools and a network of data for prosthetic fittings and use, alongside ethnographic research to ensure developed technologies are practical

FUNDER: Engineering and Physical Sciences Research Council (EPSRC), Royal Academy of Engineering (RAEng), Innovate UK

HOW DID ALEX BECOME A MECHANICAL ENGINEER?

WHO OR WHAT INSPIRED YOU TO BECOME AN ENGINEER?

Both my grandfathers were engineers (one by profession, and the other at home in the garage) so I became an engineer due to nature and nurture!

WHAT LED YOU TO SPECIALISE IN BIOMECHANICS?

I discovered biomechanical engineering by accident. I started studying mechanical engineering so that I could work in motorsport or the aerospace industry. For my dissertation, I was allocated my last choice of project, covering a carbon fibre hip replacement. I was disappointed for about two hours, until I started reading about the topic. I found out that some patients were still being fitted with implants similar to those developed in the 1960s and I realised there was a need to tackle some really fundamental challenges in biomechanics.

WHAT ARE YOUR PROUDEST CAREER ACHIEVEMENTS, SO FAR?

I am proud of seeing the hip replacement implants I helped develop in my first graduate job enter into clinical use and being implanted by surgeons around the world. More recently, I have been very proud to see my students defend PhDs, become doctors and go on to exciting jobs, including starting a company developing software to design prosthetic limbs.

WHAT CHALLENGES WILL BE ADDRESSED BY MECHANICAL ENGINEERS OF THE FUTURE?

I think we have a real challenge of balancing development, to make our lives easier and better, against sustainability, as we become more aware of our limited resources and our impact on the environment. I’m very encouraged by the awareness of these issues we now see in schoolchildren and students.

Do something you enjoy! If you like making things, writing code, building kits or fixing things, or even just taking things apart to see how they work, you might already be thinking the way an engineer does. More than that, just look at the objects in the world around you and ask yourself lots of ‘why?’ questions: Why is it that shape? Why is it made from that material? Why don’t we do that in a different way?

Do you have a question for Laurence or Alex?

Write it in the comments box below and Laurence or Alex will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)