Building and training human tendons in the lab

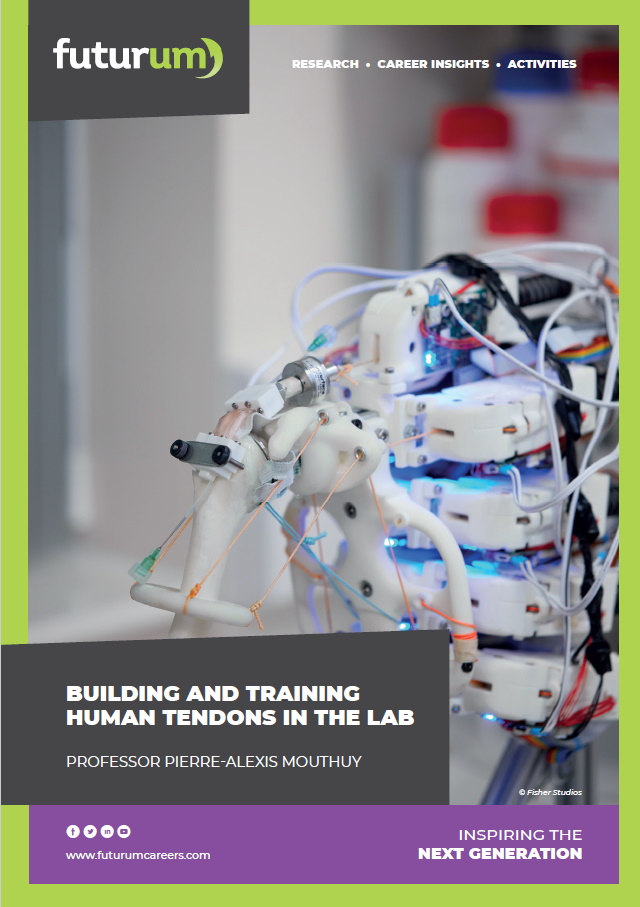

Tendon issues affect millions of people worldwide, and treatment options are far from guaranteed to be effective. Tissue engineering involves building human tissues in the lab, which can then be used to replace faulty tissues in patients. Professor Pierre-Alexis Mouthuy, based at the University of Oxford in the UK, is taking this a step further with tendon building, by using humanoid robotic arms and soft bioreactor chambers to ‘train’ tendons to deal with the stresses they will encounter in the human body.

TALK LIKE A… BIOENGINEER

Bioengineering — the application of engineering principles to the fields of medicine and biology

Bioreactor — equipment within which a biological process is carried out

In vitro — (Latin for ‘in the glass’) used to describe processes taking place in the lab

In vivo — (Latin for ‘in the living body’) used to describe processes which happen within living organisms

Mechanical — in a bioengineering context, something involving movements, such as rotations, stretches, compressions or twists

Musculoskeletal — relating to muscles and skeletons, especially regarding their interactions

Orthopaedics — the branch of medicine concerning correcting structural issues with the musculoskeletal system

Polymer — a large molecule composed of repeated chains of smaller molecules

Stem cell — a cell that has not yet become specialised and has the potential to become one of many different types of cell

Tendon — soft connective tissue made, mainly, by collagen that attaches a muscle to a bone

Tenocyte — a tendon cell

Tissue — a collection of specialised cells and their products making up a functional part/structure in a living organism

Tissue engineering — a type of bioengineering involving creating in vitro tissues with the intention of restoring or improving tissues in living organisms

Our tendons are strong cords that connect our muscles to our bones, allowing us to move our limbs and absorb some of the impact of movement. While they are extremely tough tissues, their lack of elasticity means they can be relatively easily damaged through intensive exercise and can take a long time to heal. “In the UK, tendon issues are the most common type of musculoskeletal condition for which patients seek medical treatment,” says Professor Pierre-Alexis Mouthuy. “They often lead to pain and prolonged periods of disability.”

Pierre works at the Nuffield Department of Orthopaedics at the University of Oxford, where his team is working on a pioneering solution to tendon diseases and injuries. He is focusing on the tendons present at the shoulder joint, where current surgical repairs have failure rates of around 40%. In cases where full replacement is needed, tendon tissue may be taken from other parts of the patient’s body and grafted in, but this can cause complications at the donor site. Pierre believes that tissue engineering could hold the solution to significantly more successful tendon repair or replacement procedures. “Tissue engineering is a promising strategy that aims to generate grafts for tendons and other tissues in vitro,” he says. “This field is still mainly at the research stage, as we are limited by the replication capacities of existing technologies, but, if successful, it could overcome the problems of tissue grafting from existing donor tissue.”

How to build a tissue

Building human tissue from scratch is no simple task. “The first stage involves choosing a type of cell,” says Pierre. “This can be either existing tendon cells (called tenocytes) extracted from patients, or stem cells which are then exposed to specific conditions that lead them to become tenocytes.” Once the cells are selected, they are encouraged to grow and multiply on a ‘scaffold’ made of synthetic or natural polymers. “In our research group, we often use a technique called ‘electrospinning’ which uses electrical charges to create very fine fibres that resemble the natural structure that holds together the tenocytes in tendons in the body,” explains Pierre.

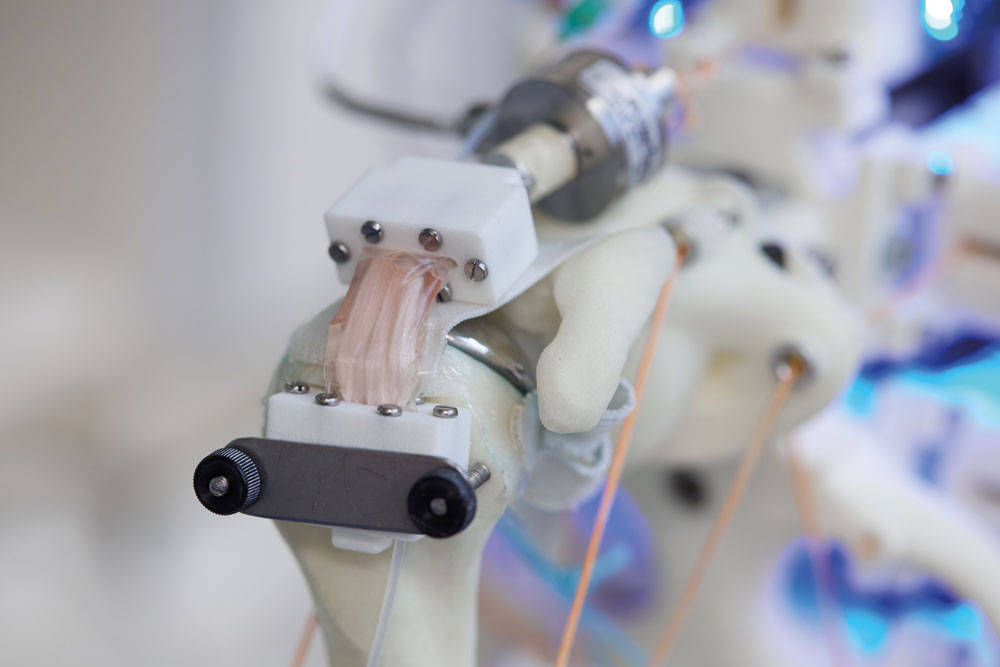

An important consideration for growing tissues in vitro is providing an environment that mimics in vivo conditions. This involves the creation of ‘bioreactors’, which attempt to provide the same chemical and physical properties as the tissue site in the body. Given the role of tendons in movement, creating effective tendon tissue involves a further step. “Cells are able to sense mechanical stresses, and this affects the genes they express, which in turn influences the proteins they produce for both internal use and external secretion,” says Pierre. “Adding simple, linear mechanical stimulation to tendon bioreactors is known to improve both the tenocytes and their contribution to their surrounding structure.” However, the body’s movements – especially at complex joints like the shoulder – do not just happen in one direction. Addressing this is the principal focus of the team’s research.

Robot shoulders

“We don’t know yet to what extent we need to mimic the body’s mechanical conditions to optimise the bioengineering of tendon tissue,” says Pierre. “Existing evidence suggests that matching in vitro mechanical conditions more closely to the body is likely to improve the quality of the tendon tissue produced.” Mimicking these conditions as closely as possible means building a working shoulder joint, which is where robotics enters the stage.

“We partnered with robotics company Devanthro, which specialises in humanoid robots,” explains Pierre. “The main challenge for our team has been to develop a bioreactor chamber that can be combined with a robotic shoulder.” To work effectively, the chamber has to be flexible and undergo mechanical stresses in different directions as the shoulder joint moves. “We went through a lot of prototyping to ensure the chamber didn’t break and remained sterile during use,” says Pierre. “We also had to adapt the robotic shoulder, which was not intended for this kind of application at all!”

Progress and next steps

“So far, we have demonstrated that we can successfully combine bioreactors and mechanical exercise, and that the forces involved do impact the growth and gene expression of the cells,” says Pierre. “While this is very preliminary work, the opportunities that this proof-of-concept study opens up are huge.” As well as practical experiments, the team has also collaborated with mathematicians and computational engineers to develop computational models that predict the effects of adjusting different parameters, without taking up the time and expense that testing these adjustments in the real world would need.

Next, the team will be working to compare the results of the robotic bioreactor system with more traditional systems that offer only linear exercises. “We need to show whether our system does make a significant difference in the quality of the tissues produced,” says Pierre. “If it does, it may provide a long-term solution for repair of shoulder tendons, leading to safer and more cost-effective patient care.” Not only that, the team’s results could be transferable to the replacement and repair of other tendons throughout the body, as well as other musculoskeletal tissues such as ligaments, cartilage and bone.

Reference

https://doi.org/10.33424/FUTURUM322

PROFESSOR PIERRE-ALEXIS MOUTHUY

PROFESSOR PIERRE-ALEXIS MOUTHUY

Nuffield Department of Orthopaedics, Rheumatology and Musculoskeletal Sciences, University of Oxford, UK

Field of research: Bioengineering

Research project: Developing a humanoid bioreactor for tendon tissue engineering

Funders: Engineering and Physical Sciences Research Council (UKRI-EPSRC) (grant number EP/S003509/1)

ABOUT BIOENGINEERING

Bioengineering is where engineering meets medicine. It involves taking the principles of biology and the tools of

engineering to create useful products for a variety of applications. As well as tissue engineering, as in Pierre’ research, there are many other areas to the discipline, such as:

- Developing prosthetic limbs and other body parts

- Developing pharmaceuticals from biological origins, such as vaccines

- Building medical imaging technology or disease diagnostic devices

- Engineering bacteria to produce specific useful chemicals

“Bioengineering is a broad and ever-expanding field,” says Pierre. “I believe there will be an increasing number of opportunities for bioengineers in the future. There is still so much to explore, discover and invent!”

Pathway from school to bioengineering

Pierre recommends considering subjects such as physics, maths, biology and chemistry in school and college. A number of universities run undergraduate courses in bioengineering or biomedical engineering, and careers in the field are also often accessible with relevant qualifications in medicine, engineering or biology.

Pierre suggests talking to people who have studied bioengineering or work in the field to gain a deeper insight into the subject and related career paths. At university, he recommends gaining research experience through lab visits and internships. Reading articles or books related to life sciences will also help develop your interests.

Nicole, a PhD student working with Pierre, recommends looking into opportunities to study abroad. She suggests researching relevant charities, as well as funding specific to certain countries or circumstances. She says you should not be afraid to reach out to research groups in search of practical experience.

Explore careers in Bioengineering

• Pierre’ department runs work experience annually, in the summer term, for Year 12 students (mostly from Oxfordshire state schools), with applications open from November to January.

• Pierre’ department also runs a monthly online talk about careers in medical research, which are later available on YouTube.

• There are many resources online exploring possible careers in the field of bioengineering. This page from Imperial College London provides a useful overview.

• According to Prospects, the average entry-level UK salary for a biomedical engineer is around £25,000 to £30,000, rising up to £45,000 or beyond with experience.

How did Pierre become a bioengineer?

As a kid, I enjoyed playing sports, board games, guitar and many other things. I grew up in Belgium, so I also spent a lot of time reading comics (which are very popular there), especially those based on science fiction and fantasy. Later, as a teenager, I developed interests in life sciences and astronomy, although I was most interested in spending time with friends!

Science fiction has been a major source of inspiration for me. I have always been fascinated by innovations and visionary ideas around engineering and medicine, regardless of whether they were real or not.

I always remember the advice to “do what you love” when making career choices. Of course, it doesn’t mean that you won’t have to do some things that you dislike or are difficult, but if you enjoy most of what you do, the rest is manageable!

When looking for university courses, I looked for studies in between engineering and medicine, which is how I discovered bioengineering. Following my degree, I gained research experience in biomaterials and tissue engineering through a master’s degree and then a PhD. Since then, I’ve been continuing my journey in research and academia.

My greatest hope for my work is that one day it can be helpful for patients. I enjoy developing new technologies for healthcare applications and have been fortunate to contribute to a few already, even if they are yet to reach clinics. I am also very lucky to have a wonderful team of researchers to work with.

Pierre’s top tip

Keep the ‘beginner’s mind’, as my Aikido teacher would often say. Experience, knowledge and critical thinking are essential in science, but keeping an attitude of openness, excitement and willingness to learn without preconceptions is also crucial. This can be easily lost as you gain expertise!

Meet Nicole

Nicole Dvorak

PhD student, Nuffield Department of Orthopaedics, Rheumatology and Musculoskeletal Sciences, University of Oxford, UK

I am a final year PhD student in Professor Pierre Mouthuy’s research group. I look into the behaviour of the tendon cells within our tissue cultures, focusing on what they consume, whether they have enough oxygen and what happens if we stretch, twist or bend the structures that the cells hold onto.

In school, I disliked physics and was bad at maths. I am dyslexic, so combinations of letters and numbers confused me. It’s funny that I now deal with both daily! I liked biology and medicine but never aspired to become a doctor, as I wanted to find a cure rather than administer it. Outside of school, I loved sports and movies. I did not read much, but I loved watching documentaries on TV.

I attended a school focusing on foreign languages. Science only interested me via TV, until my final year when I wrote a small thesis on genetic disorders; that was when the spark turned into a flame. I went on to do a bachelor’s and master’s degree in medical and pharmaceutical biotechnology in Austria. These courses each included a research semester, so I went to the University of California San Francisco (UCSF), in the US, to do transplant research and the Queensland University of Technology (QUT), in Australia, to do tissue engineering. The latter topic fascinated me because of the body’s ability to heal and because it involved engineering.

Some days, I get up at 5am to go rowing, before going to work at 9am. Other days, I work from home. I have a disability, which means I need to be flexible and listen to my body. My days include planning and conducting experiments, analysing data, writing scientific papers about our results and writing my PhD thesis. I am also on committees to spread awareness of disability issues within the university.

Whether because of a question from a colleague or some unexpected experimental results, every day is challenging in a different way. That is the nature of research; we are working at the edge of our knowledge, which is what makes it exciting and rewarding.

I’m very proud of where I am now. The odds of me getting into university were not high, but I’ve always found science inherently fascinating. After I was diagnosed, I found Stephen Hawking especially inspirational.

Nicole’s top tips

01. Everyone’s timeline is different. Do it your way.

02. Be ambitious.

03. Ask questions unapologetically.

Do you have a question for Pierre or Nicole?

Write it in the comments box below and Pierre or Nicole will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)

Hello Nicole,

It’s a fascinating science you do all.

In how many yea6 will it be a routine to transplant trained tendons ?

Best wishes for the final thesis work and the future.

Csilla and Joseph